Description

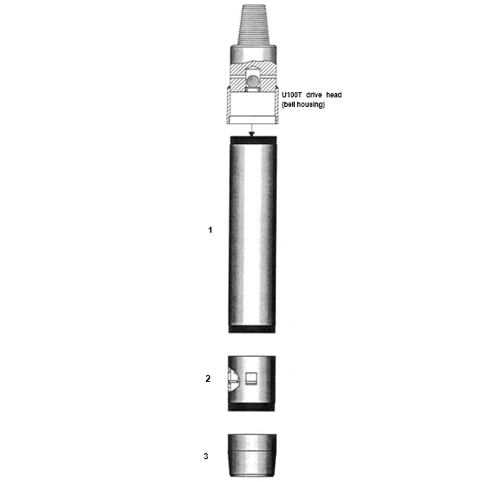

This equipment is designed for taking class ‘A’ samples in clay and other soft formations. The sample tubes are each 18″ long and are driven into the ground using a sliding hammer with U100T drive head (bell housing) attached. The drive head contains a ball valve to allow air to be released from the upper part of the sample tube as it is being driven into the ground.

Only one type of U100T sampling system is currently manufactured:

Thin walled sampling system

Consists of steel, cadmium-plated steel or aluminium sample tubes, an optional corecatcher and a case-hardened drive shoe. The drive shoes are supplied with a plain cutting edge. Plastic push-on caps can be provided for the sample tubes and a special sealing wax for long-term storage.

The difference between the standard sampling system and the thin walled sampling system is that the area ratio as defined in EN ISO 22475-1:2006 is 15% or less and the cutting shoe taper angle should be 5% or less which allows a Class A sample to be taken. It should be noted that the sampling shoe is thinner than a standard U100 sampling tube so needs to be handled with care so that the sharp cutting edge of the shoe is not blunted.

[ultimatetables 14 /]

* Dimensions measured on the cutting shoe

U100T Standard system

1. Sample tube (steel,cadmium- plated steel or stainless steel).

2. Corecatcher (optional)

3. Cutting shoe