Description

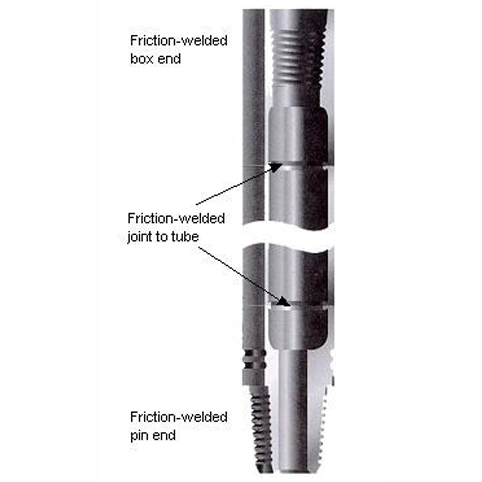

These rods have friction welded tool joints which are specially hardened and made of the highest quality steel.

The advantage of friction welding is that different steel qualities can be chosen for the mid-body section and the tool joints. A high quality alloy steel is used for the tool joints, increasing the strength in the threads where it is required, combined with a thin-wall tubular material in between, making the rods light and easier to handle.

When required an additional surface hardening can be applied to the tool joints for increased wear resistance.

The rods have spanner flats on the pin and box ends. Plastic thread protectors are available for all API connection types.

The rods are suitable for both DTH hammer and rotary drilling.

| Friction-welded Drill Rods | |||

| Rod Type | Rod O.D. in. (mm) |

Thread | |

| LPR-67 | 2.5/8″ | 66.7 | NWY |

| LPR-76 | 3″ | 76.2 | 2.3/8″ API Reg |

| LPR-89 | 3.1/2″ | 88.9 | 2.3/8″ API Reg |

| 2.3/8″ API I.F. | |||

| 2.7/8″ API Reg | |||

| LPR-102 | 4″ | 101.6 | 2.3/8″ API I.F. |

| LPR-114 | 4.1/2″ | 114.3 | 2.3/8″ API I.F. |

| 2.7/8″ API Reg | |||

| LPR-127 | 5″ | 127.0 | 3.1/2″ API I.F. |

| LPR-140 | 5.1/2″ | 139.7 | 4.1/2″ API Reg |

| Standard effective lengths are 3000 and 1500 mm. Other lengths manufactured to order. | |||